Scott Nelles

Scott's beautiful metal sculptures have a pulpy retro aesthetic and are created by hand using the "sand casting method" right here in the USA!

Scott's beautiful metal sculptures have a pulpy retro aesthetic and are created by hand using the "sand casting method" right here in the USA!

Scott Nelles (pronounced "nell-ess") creates cast bronze sculpture by using the trades of industry. Much of the inspiration for his work actually comes from the process in which he makes it.

Cast metal toy rockets, ray guns, and flying saucers take him back to his childhood in Detroit where his father, a manufacturers representative, would take Scott on factory tours. The dramatic sight and heat of molten metal became a part of his soul and the excitement of the foundry process has never left him.

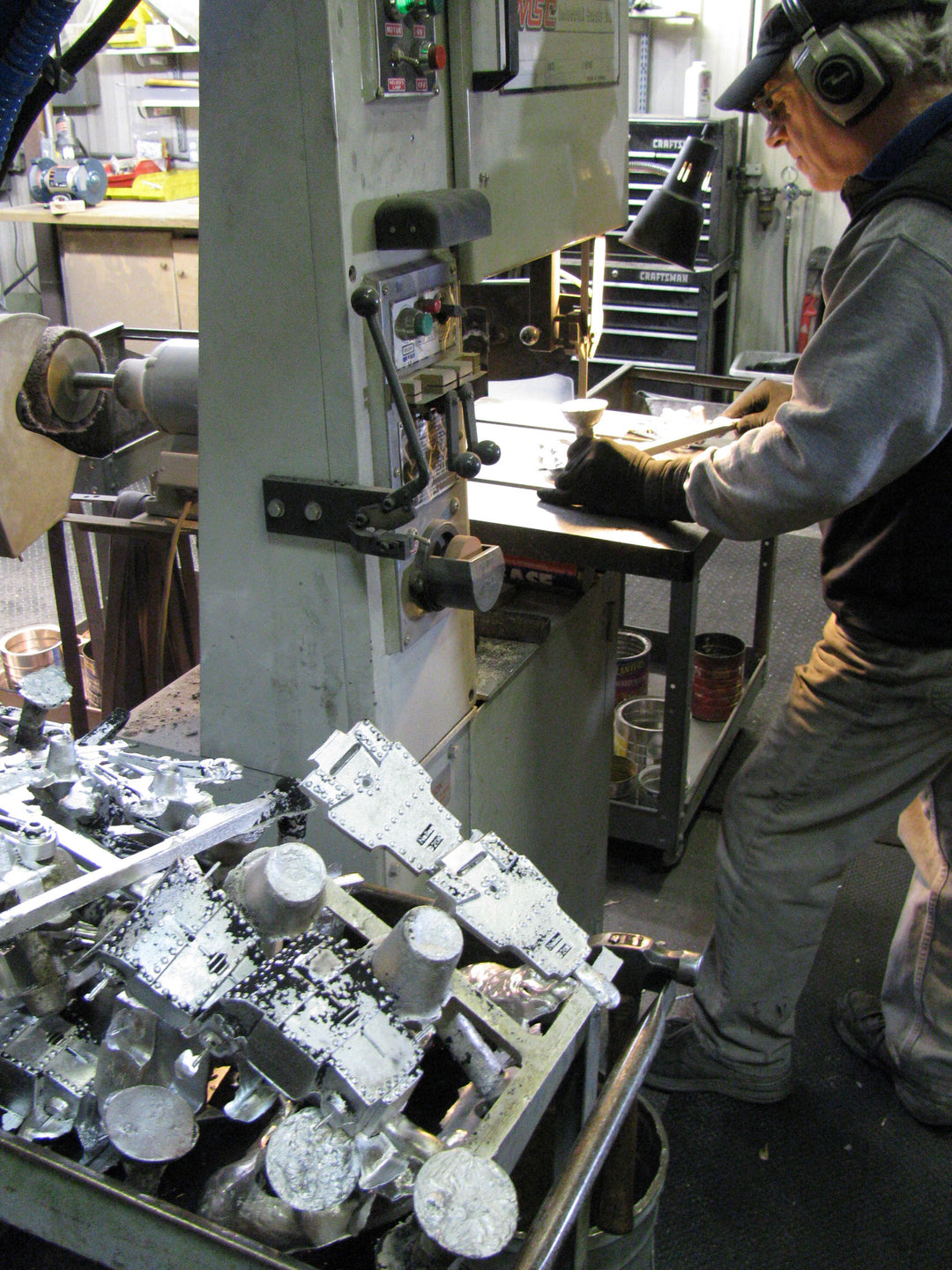

Many people are aware of the "lost wax method" of creating bronze castings and sculpture. Scott Nelles on the other hand creates his art by using the "sand casting method". This process is seldom used in the arts and very few are aware of its possibilities. Scott has tried to take advantage of his process to express his artistic visions and also make his art more available to the public.

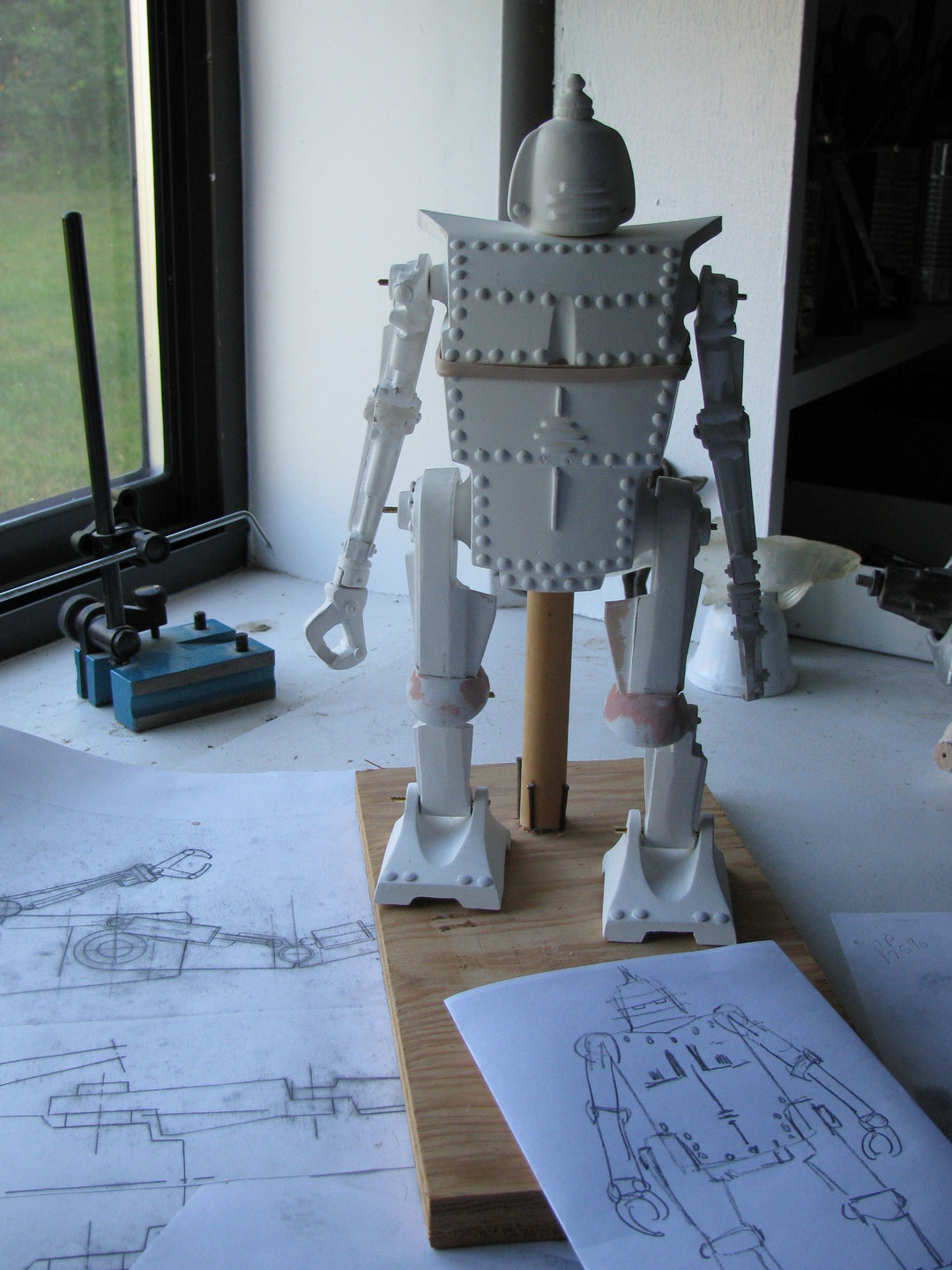

To be a sculptor and founder of bronze entails many skills and the use of many materials. Some people work only in wood, others work in clay or glass. Scott works in a variety of materials to develop a pattern or model of his sculpture. He might make a model with wax or oil based clays. Other materials important to the “pattern-making” stage are wood, plastics, and resins of all kinds. Sheet metal and fabrication, welding and forging all come into play as well. When a concept is created in one material or a combination of materials, Scott then needs to make a series of molds of the original model. These molds can be made in plaster, various poured resin materials, or sand. A final pattern is made in a rigid material like polyurethane plastic or cast aluminum.

Using this pattern called a “match plate,” Scott can make rammed sand molds off of it in the foundry. Bronze casts are then made at 2150 degrees F using the sand molds. When the metal cools, he shakes the sand away and a rough casting of the original sculpture emerges. Many types of finishing operations follow – including cutting, belt sanding, die grinding, sand blasting, tumbling, oxidizing, polishing, and lacquering.

©Scott Nelles